The Capsule

A little over 120 years ago, the elusive and radically advanced Jovian Directorate gifted a small Caldari megacorporation with the blueprint and designs for a piece of technology that was to radically change the fate of the human race.

For a small, select, and chosen group of individuals, those with the physical and mental durability to survive the transition into posthumanism, this technology would provide the gateway to power and riches beyond their wildest dreams and with it, near immortality.

This piece of technology is known today by most as the pod or capsule. To give the device its full name, we would call it the hydrostatic capsule, and we would call the pilot encased within its armored shell a capsuleer.

Background

For thousands of years after the Dark Ages, when the Age of Expansion began, humanity fought a war against the ultimate paradox. The perils and sheer inhospitable nature of space travel versus the need to expand and colonize for our species to further develop itself.

Along the way over the last seven millennia, many historic and groundbreaking discoveries were made that changed the face of interstellar exploration: the rediscovery of warp technology, the construction of the first stargates since the devastating collapse of the EVE Gate, faster-than-light communication—all of which paled in comparison to the arrival of the hydrostatic capsule in terms of consequence for the human race.

A single device that, when melded with today’s cloning advancements and neural and nanotechnology, can grant those select few the gift of lightning fast reaction, command over the most powerful starships ever constructed with the power of thought alone, and most importantly for many, near immortality.

With the dawn of the capsuleer came a new age. The Age of Expansion was left behind, written into the books of New Eden's history as those chosen half a million or so pilots took to the stars, the tens of trillions they left behind looking up in awe and wonder.

In YC105, with the union between capsule and clone completed, the Empyrean Age had dawned.

Early History

Initially the first prototype capsules constructed outside the Jovian Directorate contained no support for neural data transfer and clone reanimation for those who chose to fly them. The initial designs were also notoriously hostile toward the human body in more ways than can possibly be listed in a single reference guide, due to the myriad of genetic differences between humans and their genetically enhanced Jove counterparts. When their capsule was destroyed, these pilots would find themselves just as mortal as any other starship pilot.

The Ishukone Corporation, after being given the rights and blueprints to the technology free of charge, did however persevere and endeavored to produce several working capsules. Their determination was admirable, despite even the most mentally and physically healthy pilots more than often being mindlocked, or simply killed by the extremely hostile nature of the technology.

Something of a stigma began to grow around the capsule and for years, no financial or commercial institute seemed to hold much faith in investing the funding required to change the public perception that the capsule was effectively a highly sophisticated liquid-filled coffin.

For many decades, tales of horror detailing the things that could happen to a pilot inside a capsule spread across the cluster, with many regarding those who chose to use the technology as fools with a death wish.

Even many regular pilots paled at the thought of hooking neural interfaces to their bodies and immersing themselves in what was billed as an expensive and overengineered tomb. For all the drama surrounding the capsule and its pilots, the Jove remained quiet, having made no attempt to assist with the development of the capsule to support their genetically inferior counterparts.

With more development from Ishukone, slowly over the course of the next few decades and with the outbreak of the Gallente-Caldari War, heroic stories of insane maneuvers and bravery began to emerge surrounding a handful of Caldari pilots who could withstand the intense rigors, nausea, disorientation, and mental stress of capsule flight.

These pilots were a rare breed; they took unparalleled risks due to the capsule’s fundamental and obvious flaws and with the end of the war came a temporary end to the capsule as most of the surviving pilots faded into obscurity.

For several decades, the concept of the capsule lay dormant in the minds of Ishukone scientists as the postwar recession loomed and the State picked up the pieces from the most savage war in Caldari history.

A New Beginning

For many years all across the cluster, medical advancements provided more and more revolutionary breakthroughs that, with the aid of cybernetic integration, enabled those with the ability to afford such luxuries the means to double, and in some instances triple, their lifespan.

Initially the process of cloning was unreliable, with only partial cloning yielding any real success, primarily used to create donor organs from the intended recipient’s stem cells to replace failing body parts.

Coupled with this, the demonization of cloning by many social and religious groups hampered the ability of scientists to delve fully into detailed research for many years due to legislation and restrictions put in place to appease the masses.

Eventually in the last couple of decades, cloning became a realistic and stable enough process to allow those with the vast wealth required for such a complex process to ensure the continuation of their lives should the worst happen.

Today many public figures, politicians, actors, heads of state, and other celebrities have the option to effectively insure their lives with an almost criminally expensive cloning contract that enables them to safeguard their future.

Similarly, some military personnel who serve as crew onboard vessels belonging to the various navies of New Eden are mandated to fly with a basic clone that is backed up every three months at the end of their service rotation. This means that if they are killed in the field, they lose a maximum of three months’ memory and training, and can be redeployed into service as soon as they have been assigned to a replacement vessel.

The Capsule & the Clone

It is not exactly known when research into the principle of bringing together the capsule and the clone was conceived, or when the capsule’s technology was dusted off and assessed for potential compatibility. However, several years ago in early YC104, a breakthrough was made that changed the principles of space flight forever.

After years of dedicated research into the workings of the human mind and its electrochemical operation, the first transneural burn scanner interface (TBSI) was successfully installed and tested onboard a newly constructed first generation prototype capsule.

Repeated testing for a little under a year saw results yield successful transfer of consciousness to a waiting donor clone in 99.7 percent of instances, a level of success and reliability that surpassed anything seen before.

The TBSI quickly became a standard part of capsule hardware during testing, evolving into what is known today as the transneural echo burn scanner (TEBS), which operates to preserve the capsuleer’s consciousness at the exact point of capsule breach.

After a further six months of vigorous testing and tireless marketing, the public perception of the capsule had been refined and primed enough for cloning contractors to begin to advertise immortality, with the support of the technology behind the union of the capsule and clone.

CONCORD immediately drew up legislation that required every capsule produced to be fitted with TEBS technology, in addition to ensuring that it was mandatory for every pilot capable of capsuleer flight to be issued with a full cloning contract, financed at their own expense or that of their employer.

Within months the capsuleer industry began to thrive, as this select group of gifted pilots took to the stars of New Eden. In mid YC105 with the passing of CONCORD's legislation via the Inner Circle's unanimous agreement, the capsuleer was born.

While the component parts of the technology used to bring the capsule and the clone remained fundamentally static since its inception, the hardware used to achieve the end results has evolved over the course of the last twenty years to be more efficient, more reliable, and far more safe, with the percentage success of consciousness transfer now fluctuating around 99.997 percent.

In YC118, after a breakthrough spearheaded by the Sisters of EVE, in part using technology developed by the Society of Conscious Thought, the CONCORD Assembly ratified legislation that authorized the use of a new type of clone, known as the “alpha clone.” The new technology utilized with this fresh breed of clone allows alpha grade clones to be preimprinted with capsule conditioning and neural control pathways without them needing to be laid down when a genetically suitable candidate undergoes clone synchronization.

Additionally, some core skill pathways can be laid down in advance, before consciousness is transferred to the clone, allowing capsuleer candidates a head start in training. Ultimately, this has more than doubled the pool of potential candidates for capsuleer training, and has almost eliminated the risk of a capsuleer becoming mindlocked.

Engineering

The principle behind the capsule is simple: to ensure the survival of the pilot of a vessel in 100 percent of cases involving the craft’s destruction, regardless of the situation. The system encompasses the most advanced technologies from a wide range of fields to achieve this goal with an error margin today of less than 0.003 percent.

There are several key components that make up the capsule and its subsystems. They all go together, and if functioning correctly they collectively ensure that a pilot encased within a capsule is effectively immortal.

The capsule is designed to act as the brain of any starship, while still being lightweight and maneuverable enough to be used as an escape vessel should the ship be destroyed or disabled.

Capsule Construction

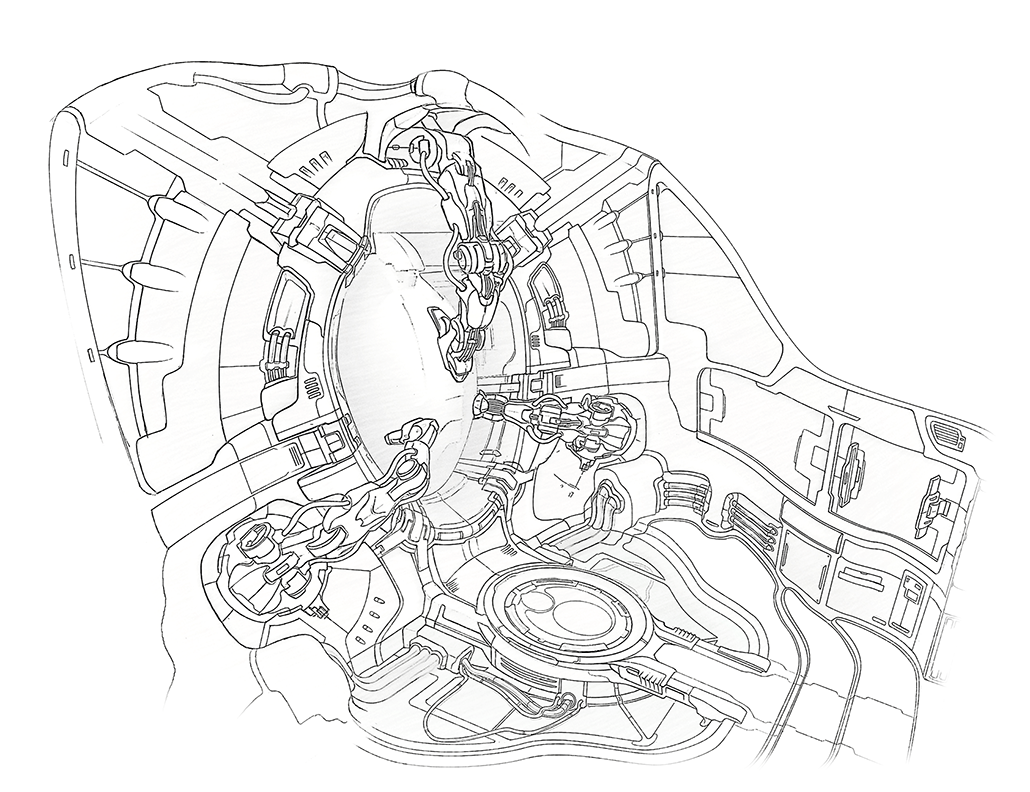

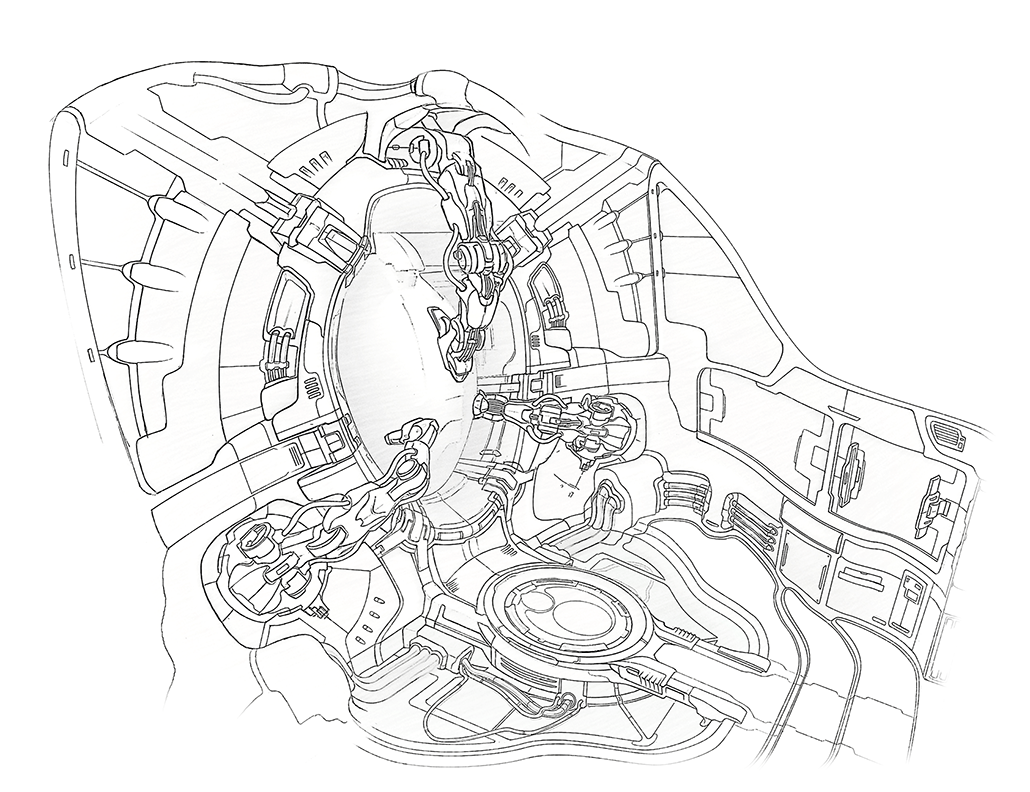

From the outside moving in, the capsule is a complex and highly strung web of technologies that bond together to protect and seal off the pilot from the elements while still giving full awareness and neural control over his or her vessel.

The external hull of the capsule seen to the observer is constructed from a 100 millimeter para-aramid carbon fiber impregnated variation of the titanium diborite armor plating used in most Caldari derived starship hulls. While formidable on its own, the addition of a strong fiber weave to the structure of the armor gives it a ballistic stopping power almost ten times greater than that of standard diborite armor of the same thickness.

This enables the thickness of the armor used on the external hull to be vastly reduced to save on mass, increasing the capsule’s inertia rating and maneuverability to aid in its use as a means of escape for the pilot.

Beneath the outer armor, behind a 200 millimeter expansion gap which is exposed to vacuum, lies the internal pressure sealed hull of the capsule itself. Known more commonly as the “stage two” hull, it is comprised of two interleaved 100 millimeter thick layers of tungsten carbide armor to provide structural rigidity.

The external hull is rigidly connected to the stage two via a collapsible shock damping assembly at the center of each armor plate, which acts as a buffer to soften the stress of external impacts. The stage two hull is pressure sealed, providing the barrier between the environment outside and the controlled internal environment of the capsule.

Inside the stage two hull, a second air gap of 300 millimeters lies between the inner surface of the hull and the outer side of the silicate reinforced polycarbonate glass suspension chamber, inside which rests the capsuleer.

This 300 millimeter air gap protects the suspension chamber, technically known as the ovum, which is attached to the stage two hull at the crown (top) and foot (bottom) of the capsule in a pair of dampened retaining assemblies. To prevent lateral movement of the ovum, the same system as between the stage two and external hull is used in a ring around the chamber at the capsule’s widest point.

The air gap between the chamber and stage two hull is pressurized to atmospheric standard pressure (1.0 bar / 100 kPA). This air gap is monitored constantly during the capsule’s operation and provides the trigger for the initiation of the TEBS (transneural echo burn scanner) system if the hull is breached or other factors cause an internal pressure deviation of more than +/- 0.01 bar.

Protection of the ovum is paramount, as within this lies the most valuable cargo that a starship has ever carried: the capsuleer, immersed in an oxygen rich, nanosaturated breathable fluorocarbon derived suspension solution.

The ovum itself is of no spectacular construction to behold. A convex, egg like silicate glass bubble with a single 950 millimeter wide circular port at its base for access and egress, and two smaller 150 millimeter ports at either side of its crown within the retaining assembly for the circulation of suspension fluid when the capsule is in service with a vessel.

Within the chamber, the capsuleer is immersed in the amber colored low viscosity, breathable suspension solution, also pressurized at atmospheric standard. The capsuleer’s lungs are flooded with this fluid on immersion, allowing the pilot to breathe liquid for the duration of their flight, with the solution’s bionanite rich composition acting as a carbon dioxide scrubber.

The liquid suspension helps in further cushioning them from the rigors of faster than light travel and external impact, stabilizing lung and body pressure in space, as well as being rich in nutrients and antibacterial nanite compounds that assist in maintaining hygiene and a sterile environment for the pilot.

Onboard Engineering Systems

The capsule has extremely low power requirements given its small size and limited onboard functionality. It possesses no local offensive weapons systems, or defensive repair systems.

When operating under its own power the current iteration of the vessel (the MK3 capsule) is powered by a scaled down Ishukone derived graviton reactor based on the Lai Dai designed unit seen widely in use today in the Harpy class assault frigate. Earlier versions of the capsule used a similar unit scaled down from the Griffin class frigate.

This tiny unit gives a total offering of 1.15 mW of potential power output to support the capsule’s subsystems and is linked to twin second generation scalar semiorganic capacitor banks to power the propulsion system, which provide an operational energy storage capacity of 125 GJ.

The twin capacitor banks provide power to the vessel’s FTL warp drive assembly, as well as the subwarp magpulse propulsion system derived from a single assembly normally seen powering most commercial Caldari designed shuttles. The capsule’s propulsion system assembly retains the standard directional thruster designs, but is rated smaller due to its size, producing 0.25 MN at maximum power.

Power for NILS, the NIA, and TEBS systems are provided directly from the vessel’s reactor, running through a full bridge rectifier and smoothing capacitors where appropriate depending on each system’s requirement, to prevent voltage or current fluctuations from propulsion and warp core demands.

The entire vessel is operated and controlled via the capsuleer through the NIA, with an Ishukone designed third generation quantum microprocessor matrix providing the processing power for internal flight control. The matrix also provides the processing power for the EIS, which controls interaction with the vessel currently in service.

Transneural Echo Burn Scanner

The Transneural Echo Burn Scanner (TEBS) system lies dormant during normal flight, monitoring information from the NILS system as well as from the propulsion, guidance, and pressure monitoring systems of the capsule. It consists of the neural echo scanner itself, as well as an ultrahigh gain FTL burst broadcast array for the transmission of captured neural data.

Stored in a separately armored pressure hull at the crown of the capsule, the device constantly monitors life support readouts from the capsuleer at a polling rate of one picosecond, as well as data from the propulsion and guidance systems, reactor, and most importantly the pressure readout from the air gap beneath the stage two hull.

Destruction of the capsule, or more specifically a sufficient drop in pressure beneath the stage two hull, triggers the TEBS into action, which is near instantaneous and occurs within five picoseconds.

Firstly, in two nanoseconds the hardware completes a highly destructive deep neural scan of the capsuleer’s skull, recording the status of every neuron within their brain, along with all vital medical statistics including blood pressure, heart rate, and blood oxygen level. The pilot is then euthanized with a direct 10 milliliter injection of a methylmercury-based neurotoxin to the adrenal cortex.

Secondly, the entire data package, which can be several petabytes in size, is burst transmitted to the capsuleer’s cloning facility as stipulated in their cloning contract.

The entire process takes five nanoseconds, with the powerful neurotoxin ensuring instant death on injection. If all goes well, the subject awakens a short while later inside a CRU (clone reanimation unit) at his chosen medical facility, with memory retention up until the point of death.

Neural Interface Life Support

The Neural Interface Life Support (NILS) system is responsible for the monitoring and well-being of its host, and the sustainment of his or her environment within the capsule.

The NILS is in contact and maintains a constant exchange of data with the TEBS system, drawing its statistics from the NIA, which attaches it directly to the capsuleer’s central nervous system.

This hardware is used only as a method of monitoring and recording data, and passing it between the TEBS and NIA hardware.

In certain instances, when the capsuleer’s vital signs may fail, or the internal environment of the capsule becomes unsafe for the capsuleer or incapable of sustaining life, the NILS system is the only piece of hardware able to administer an override call to the TEBS system to initiate the deep scanning process.

Neural Interface Array

The link between human and machine, the Neural Interface Array (NIA) is the most sophisticated piece of hardware installed in a capsule. Capable of taking biological readouts and statistics and converting them to digital data for processing by other capsule subsystems, the NIA is the linchpin of the entire operation, and links the host to the rest of the capsule’s hardware.

The NIA is fundamental for the operation of the capsule, utilizing ultrahigh bandwidth neural jacks grafted directly to the capsuleer’s spinal cord. These intercept bioelectrical signals from the brain, relaying them to the capsule’s processing matrix and the EIS for processing and conversion into usable data, before transmission to the vessel that the capsule is currently in service with.

Physically, the NIA is a free-floating device connected to the internal wall of the capsule’s suspension chamber by a flexible and extendible ultrahigh bandwidth umbilicus that allows limited flotation movement of the capsuleer within the chamber during flight.

The neural jacks lock into the interface on the host’s spine, with a vacuum-sealed support matrix that extends out as far as the capsuleer’s shoulder blades to support full body weight during immersion and decanting procedures.

External Interfacing System

The capsule’s onboard processing system used for its own control also includes a dedicated External Interfacing System (EIS) for communication of commands to the vessel currently in service.

Connected to all but one of the capsule and ship’s systems, the EIS is the single gateway in ship to capsule communication, streaming hundreds of petabytes of live data and commands between the ship and the capsuleer via the control umbilicus.

The only capsule system that the EIS is refused hardwired access to by design is the TEBS system, for the capsuleer’s protection from external interference during immersion.

Housed beneath a protective crown cone at the nose of the capsule, the control umbilicus interface is well protected until the capsule is secured within the vessel in service. Once in place, typically in an inverted orientation so that the nose becomes the bottom of the capsule, the nose cone splits and retracts to reveal the ship to capsule interface, or SCI.

Once the capsule has been installed in the ship and is safely secured, the control umbilicus extends from the vessel to meet the SCI and locks in place. Along with this, two pressure sealed hoses are also attached to the EIS interface to allow the vessel to circulate, purify, and carbon scrub the capsuleer’s suspension fluid, enabling the pilot to stay immersed for long periods of time.

The control umbilicus itself is classed as part of the vessel in service rather than the capsule and for practical purposes, offers near limitless bandwidth for communication between the capsuleer and the subsystems of the attached craft.

Once the capsule and starship are successfully interfaced via the EIS, the capsuleer effectively becomes part of the starship. This gestalt existence allows the pilot to maintain complete and instantaneous control over every aspect of the ship’s operation with the power of thought alone, replacing the traditional command crew seen on noncapsule derived vessels.

The Capsule Chamber

Known more commonly as “the Tank,” an affectionate nickname given by most non-capsuleer crew members, the capsule chamber is the most secure bay within any capsuleer’s vessel. It is within this armored inner sanctum that the capsule rests during flight. Constructed deep within the bowels of every vessel, this heavily armored blast shielded chamber is accessible by only one method.

Access to the chamber is permitted only via the hatch and causeway through which the Capsule travels to it. The causeway is sealed via a minimum of two heavily armored blast doors, one at the entrance to the chamber itself and the other beneath the surface of the vessel’s hull, behind the hatch, which gives access to the causeway from outside the vessel.

Usually, to maintain the smooth profile and armor integrity of a vessel, the outer hatch that leads to the tank is simply one of the armored plates of the vessel’s outer skin that when removed, reveals the causeway through which a capsule gantry can gain access. This plate is typically fitted with explosive bolts that blast it free when emergency egress is required.

Depending on the design and personal specifications of the capsuleer owner of the vessel, further hatches and security devices may be fitted to enhance the vessel’s operational safety.

To maintain structural integrity of the chamber in flight and provide maximum protection for the capsule and its pilot, the chamber itself has no other points of access, save for the various electronic interfaces that breach its walls for connection to the capsule.

During flight, the inside of the tank is not pressurized and remains exposed to vacuum to further enhance security and provide a more controlled environment for the capsule’s subsystems to operate. This is achieved by locking down the access causeway, but not pressure sealing the armored blast doors, which protect the area from intrusion.

In the rare event that emergency access to the capsule chamber is required during space flight, the capsuleer can at his or her discretion authorize the release of the hatches and the firing of the outer explosive bolts so that maintenance personnel with the correct protective equipment for working in vacuum can gain access to the chamber.

When stationside, the causeway takes on the atmospheric characteristics of the hangar, and once the capsule is removed to undergo the decanting process, access to the chamber is typically free flowing for specifically authorized personnel.

Please note that the cutaway technical specifications shown within this reference guide deliberately do not display the structure and layout of the causeway or the capsule chamber both for clarity of the systems around it and for security reasons, as many of the specifications used in construction of this part of a vessel remain classified and vary depending on an individual capsuleer’s security specifications.

The construction principles of the causeway and capsule chamber are carried throughout all capsuleer capable vessels, although depending on the cultural origin and design of the starship in question, construction materials and specific security measures may vary.

Hydrostatic Fluid

Usually known to capsuleers by its affectionate name of “pod goo,” the hydrostatic fluid used in the capsule is a complex and perfectly balanced self-sustaining ecosystem that supports, nourishes, and maintains the capsuleer’s physical health while he or she is immersed.

To give it its full name, we would technically call the liquid an oxygen rich, nano-saturated, breathable glucose based suspension solution.

The entire solution is formed around a base of common carbohydrate glucose with various nutrients, vitamins and minerals amalgamated into the base compound along with several variations of bionanites that assist with life support.

For purposes of liquid respiration, the solution remains oxygen rich, with an infusion of nanotechnology designed to absorb carbon dioxide from the capsuleer’s lungs, and break it into component parts before releasing paired oxygen molecules back into the fluid.

During normal flight, the hydrostatic fluid is circulated within the capsule and drawn out through the attached vessel’s life support system where the fluid is carbon scrubbed to prevent lethal buildup. Coupled with respiration, the fluid provides the base nutrients and vitamins required to sustain the capsuleer for extended periods of time in flight.

The Capsule’s States of Operation

During its life cycle, a capsule will have four states of operation within normal design parameters. These states do of course depend on the capsuleer’s current environment and the situation in which the capsule is used.

In Service

In service the capsule is retained within the capsule chamber, secured by four air over oil dampened hydraulic retaining clamps which act to absorb the stresses and movement of the vessel around it, keeping movement of the capsule to a minimum in relation to the vessel’s superstructure and artificial gravity well.

Typically, the capsule is inaccessible to physical external influence during this state, and operates with the capsuleer sealed inside and isolated from the elements. In this state the capsule’s own reactor, power core, and propulsion system are shut down for self-diagnosis and automated maintenance while it draws power from the vessel via the control umbilicus.

When in this state, the Capsule’s hydrostatic fluid is circulated and carbon scrubbed by the vessel’s life support subsystem, and a perfect ecological balance within the suspension solution is maintained via intricate monitoring of the fluid’s composition, with the fully automated system maintaining balance.

In theory, and disregarding the mental implications of spending extended lengths of time immersed, in this state the capsule is capable of sustaining life support for the capsuleer indefinitely.

In Free Flight

Under normal circumstances if the capsuleer chooses to eject from his or her vessel the control umbilicus is shut down and safely uncoupled after the capsule’s own reactor and power core are brought into service.

At the same time the hydrostatic fluid circulation hoses are pressure sealed and retracted. The electromagnetic seals of the retaining clamps are then released along with the hatches to the access causeway.

The capsule is then automatically guided free of the vessel under its own power before control is relinquished to the pilot.

Operating under its own power, the capsule will provide approximately 180 days of life support for the pilot, before the solution and the nanites within become saturated with carbon and are unable to further process carbon dioxide. At this point, the neural interface life support will trigger the TEBS, euthanizing the pilot and returning them to their chosen cloning facility.

When operating in this mode, separated from a vessel, the capsule utilizes its own onboard reactor, power core, sub-light propulsion systems, and warp core.

In Maintenance

From time to time a capsuleer will feel the need to dock, stretch their legs, and go about their business. When this is the case, the capsule is retained within the capsule gantry, commonly referred to as the pod gantry, attached to the pilot’s secure accommodation.

Here, the capsule can be unsealed, split, and the capsuleer can be safely decanted and go about their business.

During maintenance, the capsule is typically in a state of hibernation while the hydrostatic fluid is flushed and destroyed. When the capsuleer is ready to resume flight, fresh fluid is used to refill and pressurize the hydrostatic suspension chamber.

During downtime, the capsule remains connected to the gantry and is in a constant state of self-testing and readiness, with all systems being periodically checked for correct function and operation.

In Emergency Service

In an emergency situation, time is of the utmost importance. Therefore, the separation procedure between capsule and vessel is much more direct and destructive once the capsule detects that it may be in harm’s way.

Typically, a single trigger will push the capsule into emergency service mode, changing its operational protocol from that of a vessel control system to an emergency lifeboat. The process for separation can take as little as a single second, perhaps two at the most.

Firstly, the EIS receives a distress call from the vessel. Typically, this is a “ship is out of control” relay broadcast from the attached vessel’s gyroscopic and navigational monitoring systems, but may sometimes also take the form of a notification of critical atmosphere containment failure due to vessel hull breach or reactor containment field failure.

When this call is received, the capsule’s own reactor, power core, and propulsion systems are immediately brought online from the state of maintenance hibernation. Simultaneously, the hydraulic retaining clamps are depressurized via explosive destruction of their control valves, which forcibly retracts them back into the walls of the capsule chamber to prevent external damage to the capsule, while the control umbilicus link is disabled and thrown loose.

The third stage is the shutoff of hydrostatic fluid circulation. The ports are immediately sealed on the ship to capsule interface, the hoses fired loose, and the inner causeway seal is released to allow capsule egress.

The final stage is the forced ejection of the capsule. Effectively, it is fired from the causeway as a projectile would be fired from a gun using an overcharged burn of its sublight propulsion system. Once it is thrown free of the vessel, its onboard guidance and propulsion systems bring it to stable rest.

Capsule Variations

Over the last decade or so since the initial union of capsule and clone, the basic operating principle of the hardware has remained the same. Small revisions have however been made to the capsule and its subsystems over the years, allowing further licensed improvement on the initial designs drafted up by the Ishukone Corporation from the technical data they received.

MK1 Capsule

In Service Early YC104 to Late YC109

The MK1 was the initial drafted design of the capsule, recognized mostly for the diamond patterned dark brownish tinted appearance of its 75 millimeter para-aramid carbon fiber impregnated external armor plating.

Initially this variation of the unit came with a scaled down version of the Griffin’s graviton reactor and power core, along with a single first generation scalar semiorganic capacitor bank that produced the 125 GJ of operational charging capacity required for operation.

This unit’s main difference from those in operation today was only apparent once it was split to allow the decanting process, with the outer hulls of the unit splitting at the capsule’s widest point, allowing the top half to be hoisted away by the capsule gantry.

MK2 Capsule

In Service Late YC109 to Mid YC111

The MK2 retained many of the features of the initial design, but with an upgrade to twin scalar semiorganic capacitor banks wired to the vessel’s graviton reactor in parallel, to provide equal charging and more stable voltage and power distribution with less stress on the bank.

The external armor plating was also improved upon, with a revised heavier carbon weave, and larger plates with an increase in penetration protection of 100 millimeters. This variation of the capsule did however maintain the center split opening method of the original units designed by Ishukone.

This variation of the capsule saw the shortest service life of any unit to date, with an upcoming revision of the propulsion system and sub-structure already in the pipeline when the revised blueprints were published.

MK3 Capsule

In Service Mid YC111 to YC119

The MK3 saw the largest revision of the capsule’s substructure so far, and the complete redesign of the reactor system.

The external and stage two hulls were, for want of a better phrase, completely redesigned, to enable a much more hygienic and convenient method of immersion and decanting. Coupled with this the refitting of stationside capsule gantries made the entire process much faster, more dignified, and more pleasant for those engaging in capsuleer flight.

In terms of hardware, a redesign of the reactor system increased power output to 1.15 mW, replacing the now aging reactor unit based on designs from the Griffin class frigate with a scaled down and vastly more efficient assembly from the Harpy class assault frigate seen in operation today.

Capsule Construction & Licensing

Capsule construction occurs in just about every corner of the cluster, with many corporations cutting a substantial profit from the fabrication of these intricate and complex pieces of hardware.

While illegal and unlicensed hardware manufacturing does happen in all corners of New Eden, generally corporations who manufacture and fabricate capsules are SCC (Secure Commerce Commission) licensed and build to a strictly controlled and periodically revised blueprint.

Capsule manufacturers supply the cluster’s major insurance corporations, with every cloning contract a capsuleer signs including the automatic replacement of their destroyed unit with a fully licensed replacement.

Many manufacturers also supply licensed independent retailers who are able to offer the units as upgrades or replacements to independent capsuleers.

On the more sinister side of the cluster’s borders, illegally manufactured units with custom modifications are widely available for reasonable prices. Often these capsules will contain the hardware appropriate for the in-flight intravenous ingestion of combat performance boosters and other such dangerous practices.

Generally, the industry is very well controlled, with a periodic revision of the capsule’s core systems to ensure the technology remains cutting edge.